How Monoflo International redesigned the Bulk Container to offer a better product with significant cost savings to the automotive and manufacturing industry.

Challenge: Design a more durable Bulk Container and drive down costs.

Monoflo International, Inc. is a premier manufacturer of superior quality injection molded plastic products and one of the first transport packaging manufacturer in the United States to make a bulk container using high-pressure injection molding. Monoflo believed that the high-pressure injection molded product line offered its customers better strength, durability, and price. Though it was outperforming the competition, Monoflo knew its first generation “G1” bulk box had room for improvement in three main areas:

» Packout Efficiency

Companies in the durable goods manufacturing industry work with a variety of vendors and suppliers, so members in that supply chain follow recommendations and best practices set by the AIAG (Automotive Industry Action Group) to standardize processes and materials, like bulk container footprints. The AIAG determined that the optimum bulk container size to accommodate the needs of the automotive industry is a48”x45”footprint. However, when loaded on a 53’ trailer, the standard bulk container footprint could leave over 290 cubic feet of unutilized space.

» Durability

The supply chain can be unforgiving. Regardless of the manufacturer, customers across the industry experienced breakage of the container’s wall hinges as a result of wear and tear and abuse. Broken containers are costly to continually replace, but if left in use, can leave the product they carry vulnerable to damages.

» Manufacturing Efficiency

Resources are finite. Increased inputs of time, energy, labor, and raw materials can collectively drive up production costs. In order to keep costs low and promote sustainability, Monoflo wanted to drive out manufacturing inefficiencies.

Solution: Monoflo’s redesigned “G2” bulk box.

Monoflo set out to reengineer its bulk box design and manufacturing process to better use the real estate in a 53’ trailer packout, improve the durability of the bulk box to withstand the rigors of the supply chain, and increase manufacturing efficiency to reduce costs.

Monoflo understood it was important that the new design maintain the same inside dimensions to be able to accommodate the same dunnage and products without disruption to current users, and needed to be fully compatible with the other containers used in the durable goods manufacturing industry. Through careful calculation and modeling, Monoflo engineers identified a way to move from a 48” x 45” external footprint to a 48” x 44.5” external footprint without impacting the dimensions inside the container or the container’s strength. The team strategically positioned the feet of the second-generation base to ensure the new model would stack with the legacy models. These changes enabled customers to fit two additional container stacks in a 53’ trailer packout.

The redesign also included modifications to improve the strength and durability of the bulk box, and offered a solution to the industry-wide hinge breakage problem. Monoflo engineers created a redesigned “Flex Hinge” without fiberglass or metal for easier assembly and disassembly, and repositioned them towards the center of the sidewall to protect from wear and tear and abuse. This also made the unit more easily repairable, providing customers the option to repair instead of replace damaged containers. The team also established an independent “T-Slot” connection between the bottom and the sidewall, offering a more precise alignment when assembled, and a box-style “Carcass Joint” to better absorb and resist impact. Lastly, using Finite Element Analysis (FEA), Monoflo implemented a “U-Channel” ribbing design down the sidewall load lines to improve both vertical and horizontal deflections and optimize stacking capacity.

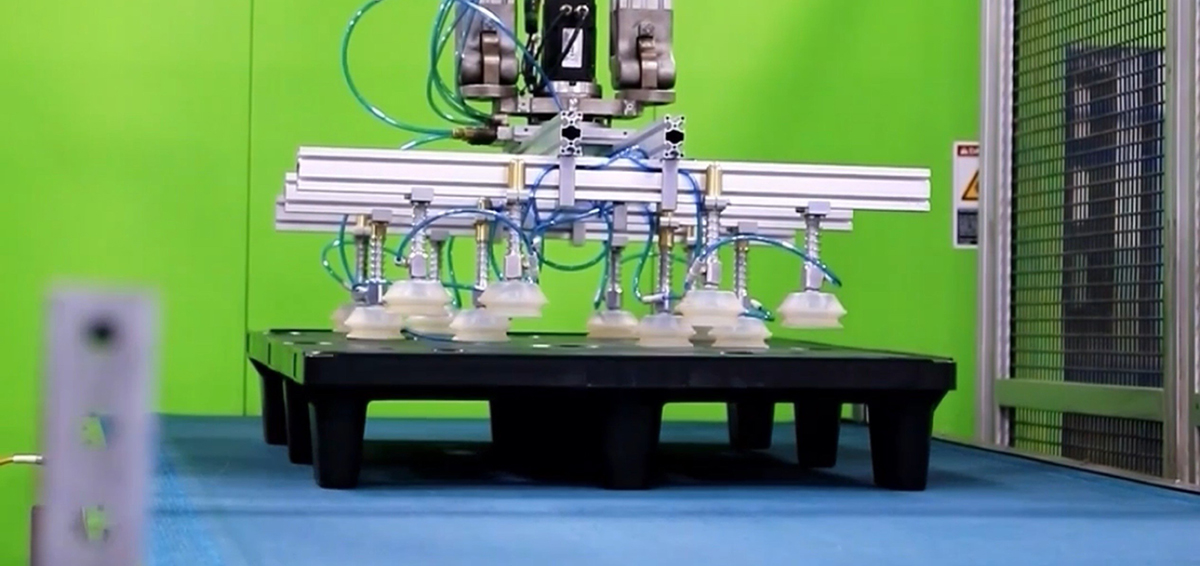

Monoflo performed a comprehensive evaluation of the machines it was using to manufacture bulk containers. Deciding it was time for an upgrade, the company made a significant, multi-million dollar investment and hand selected only the best-in-class robotics and machinery to fully automate the manufacturing process of the newly designed “G2” bulk container.

Results:

» Decreasing the external footprint of the container by 1⁄2 inch meant that 252 units could now ship in a single truck, an increase of 20% from the previous capacity of 234 units. For businesses that move thousands of truckloads of product across the country each year, this translated into significant cost savings. Customers not only pay a lower per-unit price on their initial order, but are also able to transport more product with each truckload.

» The improved“G2”Bulk Container with the new “Flex Hinge,” “T-Slot,” and“Carcass Joint” features has the highest strength-to-weight ratio in the industry as well as decreased reports of broken hinges. The “U-channel” ribbing offers improved load distribution, translating into the highest overall load stacking capacity and increased wall rigidity, both when assembled and disassembled. These strategic design optimizations enabled Monoflo to create a stronger, more durable container with improved load distribution while reducing the overall product weight by 20%, meaning less raw materials consumed and lower freight costs throughout the life of the product.

» Monoflo’s technology investment completely automated the bulk box manufacturing process, decreasing cycle times by nearly 6% and creating a manufacturing cell cost savings that Monoflo was able to pass on to customers. The upgraded technology also includes a vision verification system to inspect minute details at critical stages of production, eliminating the risk of misassembled product and guaranteeing consistent, repeatable quality.

Every factor of the redesign, from the increased packout count, to the improved durability and repairability, and the ongoing freight cost savings contributes to a lower total cost of ownership to customers. The new G2 Bulk Container offers a better quality, more durable container for a lower upfront price and freight savings for the life of the product.